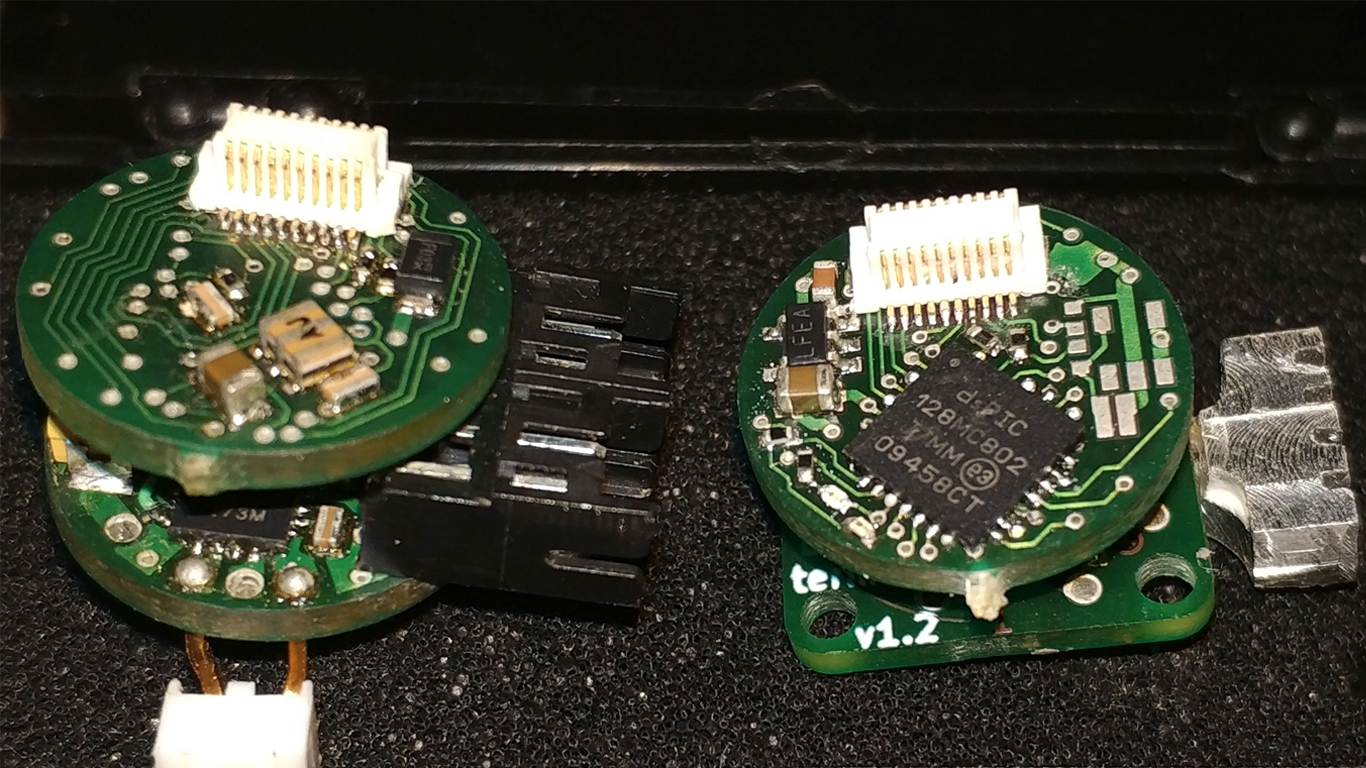

Miniature Motor Controller Board

Motivation

Observing that the mobile phone and auto markets had driven a step change in the size of components, Chris Wagner and Traveler Hauptman designed a motor controller with the goal that it should be as small as possible using average manufacturing techniques. So techniques like de-lidding and wire-bonding to silicon, or using extra small PCB features that were beyond the capability of most manufacturers, but could be done by specialists we knew, were not allowed.

Activity

We designed a modular distributed motor controller. Sensing, computation, and power were separated onto different boards so that the stack could be adjusted to the application. A power section with CANBUS comms and a 2Amp H-Bridge for DC motor control was prototyped. As was a processor board using a Microchip DSPic motor control chip.

The result was a distributed motor controller with a 16mm diameter. We iterated on the processor and power boards, building several. Pieces of this project have been re-used in other projects.